September Update

We are excited to share with you all the things we have been working on in the past two months. In this update, we will cover all the technical developments and challenges we faced as we prepare for the mass production of Shrooly, so you will know exactly what is happening.

First and foremost, we are happy to announce that we are working on delivering the last round of Beta units, and some of our Beta users are already cultivating mushrooms with them. The feedback from previous Beta rounds helped us improve Shrooly and avoid any unforeseen problems. The last prototype of Shrooly was already made based on the suggestions we got previously. We are committed to delivering a flawless product both in terms of design and functionality, so this step was crucial. We were excited to see our product being used by experienced mushroom enthusiasts and beginners alike.

Meanwhile, our Product Team is tirelessly working on the design for manufacturing (DFM) process with the engineering team of our production partner. The prototype parts are ready, and the assembly is underway. Our Team is currently at our production partner’s facility in China. Once the prototype is complete, they will participate in the last evaluation process to decide if we can move on to the tooling process or if we still need to make a few small modifications.

We chose our Chinese manufacturing partner because their extensive experience in producing home-gardening gadgets helps us to minimize the likelihood of delivering a faulty product. Since so many of you support us, it was also important to find a manufacturer that can fulfill a large volume of orders fast, and they meet this requirement too.

Shrooly Application

You might already know from our last update that our Mobile App Development Team has made remarkable progress with the Shrooly App in the last months. By now, our Beta users are already using it as they are growing mushrooms with their Shrooly.

We are very proud of our team because they did an amazing job. It is not common to develop such a detailed application for a hardware product in this phase, but we wanted to guarantee the best user experience possible.

In recent months, we finalized the flows and corrected smaller errors. We also ran extensive edge case testing to make sure everything worked flawlessly. We added a support feature connecting users to live agents and providing immediate assistance.

We are currently working on integrating new features, such as recipes and the login process.

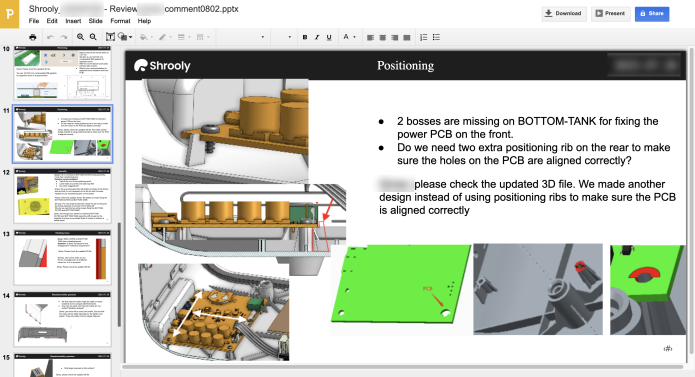

PCB

We made changes regarding the PCBAs and made sure to use parts that are readily available on the market for our first manufacturing run. This is important because we want to avoid any supply chain disruption that could cause future problems.

We decided to move the “water level and humidifier driver” PCBA to the side of the water tank and modeled a new, shorter fixing rib for it, as this will be easier to mold and more convenient for production. There were some fitting issues with the new PCB parts, but our product team has already made the necessary adjustments to solve them.

Our Electrical Engineering Team has been preparing for the new hardware version (v4.0), which has many improvements since the previous version.

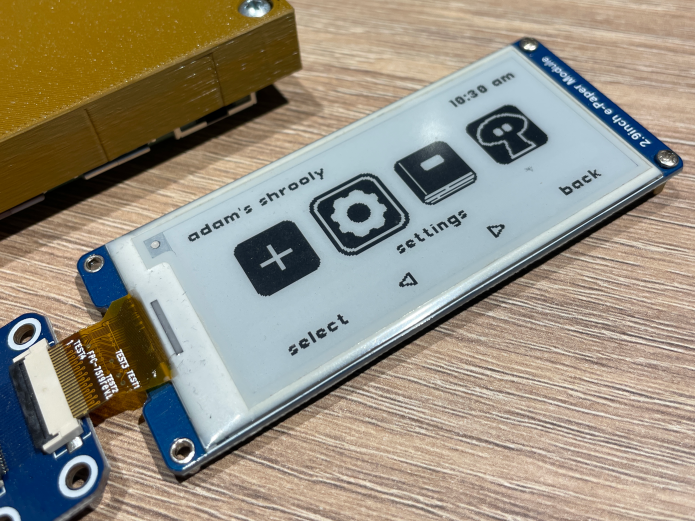

Firmware

Minor changes have been made to the E-INK screen: we display the current actions that could be done with the buttons on the e-paper display. We also installed a real-time clock, so even if the users disconnect their phones from Shrooly, the date and time will remain set to the current time even after the device has been reset.

We have also added new ways to recover the device if the internal software (firmware) has unforeseen problems. Users can connect the device to their computer via a generic USB-C cable. The device will show up as a pen drive, and users can copy the new firmware to it like they would on a computer. Then, the device will install itself, and it is ready to go again! This is a very important feature because in our experience many products stop functioning after a failed software update, which was something we wanted to avoid.

LUA

Let’s do a technical deep dive! The device stores the cultivation programs as Lua scripts. When you start a new cultivation via the mobile app, the app downloads the latest program from our servers, sends it to the device over Bluetooth, and starts the script. This way, we can iterate on the cultivation programs faster and implement new logic and cultivation methods quicker and without the need to do firmware updates each time. After months of hard work , we implemented the last detail to complete the feature: autoload. This functionality continues the cultivation program when power is lost for any reason and/or the device gets restarted.

The Lua interpreter is also in connection with our Power Panic function: when the device detects power is lost, it still stores enough energy to save the current state and other settings to have a safe startup when power is restored. It has a trick up its sleeve: it also clears the e-paper display and shows a goodbye text, so users can be sure the device is turned off.

Plastic Parts

We have also made some changes to the plastic parts of the device to make sure that they can be manufactured using injection molding.

The humidifier module had a wired connection in the previous prototype. In our tests, we realized that having connectors is not ergonomic enough; connecting or disconnecting them can be a hassle. To improve the user experience, we decided to make a change: we are moving to a wireless power transfer (WPT for short) solution. It works just like an electric toothbrush: has two coils hidden under the plastic parts for sending and receiving electrical energy for driving the humidifier fan. With this solution, we can make the humidifier unit totally waterproof! If users need to clean it, most likely because of spores, they can take it out instantly, wash it in the sink, and place it back without unplugging anything. Don’t worry: the device detects when it is removed and will alert users if they want to start a new cultivation without the humidifier installed.

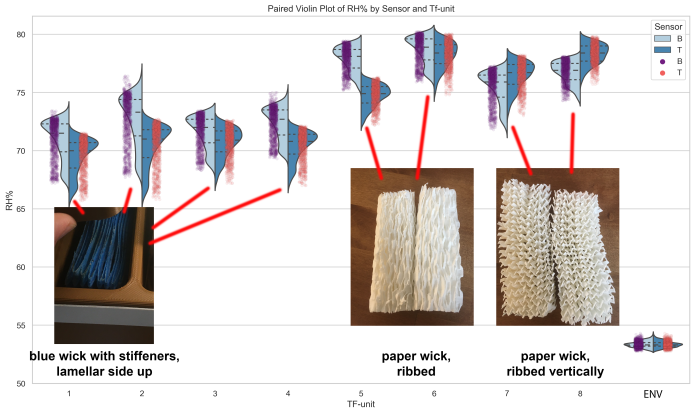

For the humidifier filter, we replaced the previous blue one made out of plastic with a paper one, it has a better humidifying effect and it is also more environmentally friendly.

We also designed a new humidifier lid with the WPT and are concluding our experiments with different patterns and holes to find the best-looking and most silent design. What you see in the video below, is an earlier model, the final product will be even more silent.

Exlusive Instagram page with regular updates

As some of you might already know, we launched a new, exclusive Instagram account for our Backers, where we share regular updates and behind-the-scenes content. Follow us at @shrooly_team on IG to see more of the developments and details of the process. You can visit our page even if you don’t have an Instagram account, just type https://www.instagram.com/shrooly_team in the search bar of your browser.

Our goal is to strengthen the relationship between the Shrooly team and our supporters because we wouldn’t have made it this far without you. We are incredibly glad to have such an amazing community around us and would like to be super transparent about the progress we are making day by day.

What's next?

Congratulations if you’ve made it this far: this is one of the longest and most detailed updates we've ever published! You probably wonder what are the next steps, so we decided to give you a short summary of what will happen in the next couple of weeks.

As we mentioned at the beginning of this update, some of our team members are currently in China at our manufacturing partner's facility. They will review the prototype so that we can get started with the tooling process.

We hope that these next steps go as smoothly as possible and we can start production soon. We know you are very eager to get your hands on the products, and our excitement grows daily as we get closer to the finish line.

As always, we are incredibly grateful for your patience and support. If you have any questions or comments, don’t hesitate to contact us! Your feedback is always appreciated.

With mush love,

The Shrooly Team